Digital ELCID & Rated Core Flux tests on Generators & Motors:

The stator core of a typical generator/ Motor is built from thousands of thin steel sheets (laminations) and the winding is formed from electrically insulated copper conductor’s bars which are embedded in slots between teeth around the bore. The core is held together by steel building bars, usually on its outside. The laminations are coated with a thin layer of electrical insulation to prevent eddy currents being induced between them by rotating magnetic flux produced by the spinning rotor.

Defects in the inter-laminar insulation cause fault currents to flow locally in the core. These currents can produce dangerous local overheating or hot spots in the damaged areas and the damage to the core may become progressively worse. In extreme cases sufficient heat is generated to melt small parts of the core and even modest rises in core temperature adjacent to the winding can result in the premature failure of the winding insulation. These hot spots should be detected and repaired during routine machine overhauls.

Rated Core Flux test:

Earlier method known as Rated core ring flux test which is normally carried out at OEM work shop, requires the core to be excited to its normal working level ( Rated flux ) for a considerable time. The temperature rise of hot spots due to the core fault was then measured. In this method many disadvantages like running of high current / high voltage cables.

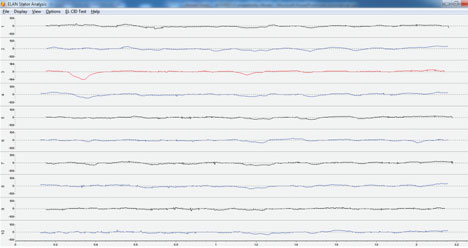

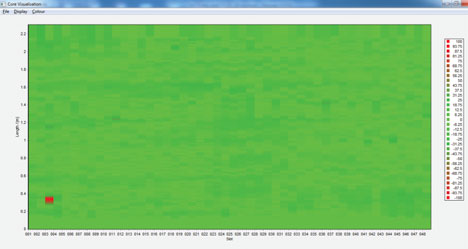

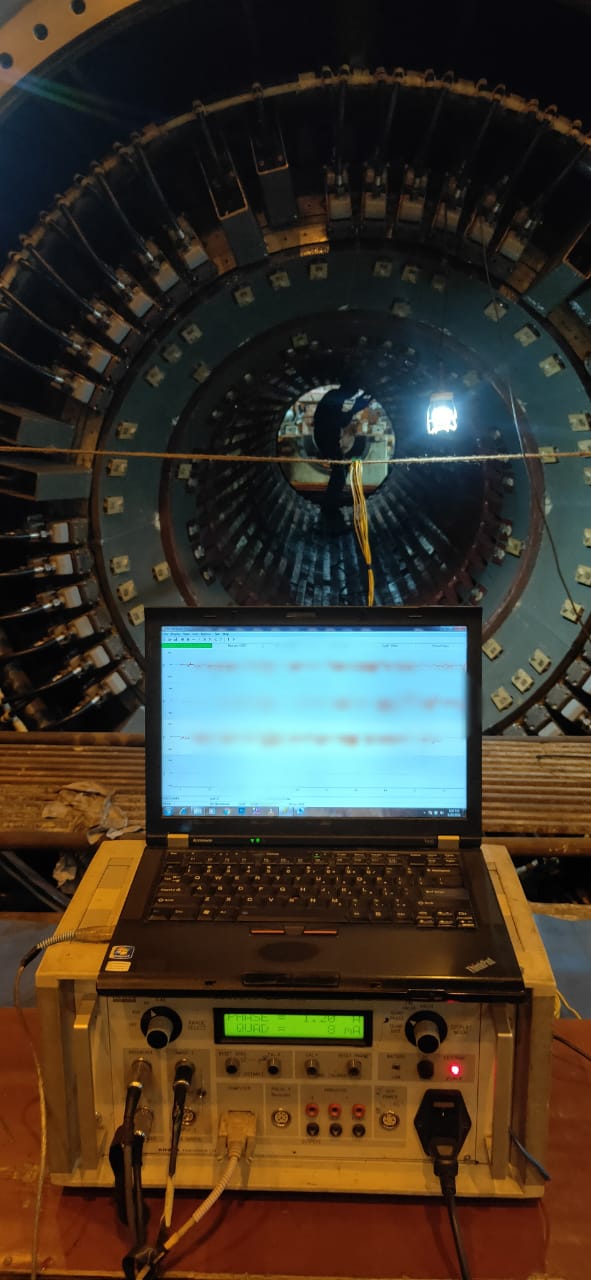

Electromagnetic Core Imperfection Detection (Digital ELCID) Test:

An alternative method of detection of faults in core interlaminations insulation by electromagnetic means is used. In this method instead of previous full flux working level, only a small fraction of rated flux (4%) is used. This technique is called Electromagnetic Core Imperfection Detection (ELCID). Power Test Asia used this technique with Computer Digital ELCID system in assessing the core condition of the machine. This equipment can assess the condition of the Generator / Motor core and gives vital information in trend analysis for use in diagnostics and predictive maintenance.

Advantages of Digital ELCID are

- Low Excitation Power - 4% with 230 V power supply

- Fast - Easy to Setup

- Low Manpower Requirements

- Significant Reduction in Safety Hazards

- Instant Interpretation of Test Results

- Minimal Risk of Further Damage

- Ability to Re-Test During Maintenance Cycle

- Permanent Data Storage

Powertest ASIA can carry out both the above tests as per customer requirements.